Aubrey Sauvie, a middle-schooler from Tennessee, was born as a triple congenital amputee, lacking limbs below both of her elbows and a foot missing toes. However, her disability is just a small part of what makes her a fascinating person.

WKRN spoke with Sauvie and she stated that having a prosthetic limb is only a small aspect of her identity and does not define her as a person.

Sauvie, at the age of 12, has accomplished quite a bit. She has achieved a black belt in tae kwon do, competes in dance, and plays the snare drum in her middle school band.

Sauvie faced some challenges while playing the drums as she found that the sticks would start slipping, despite her proven success in almost everything she does.

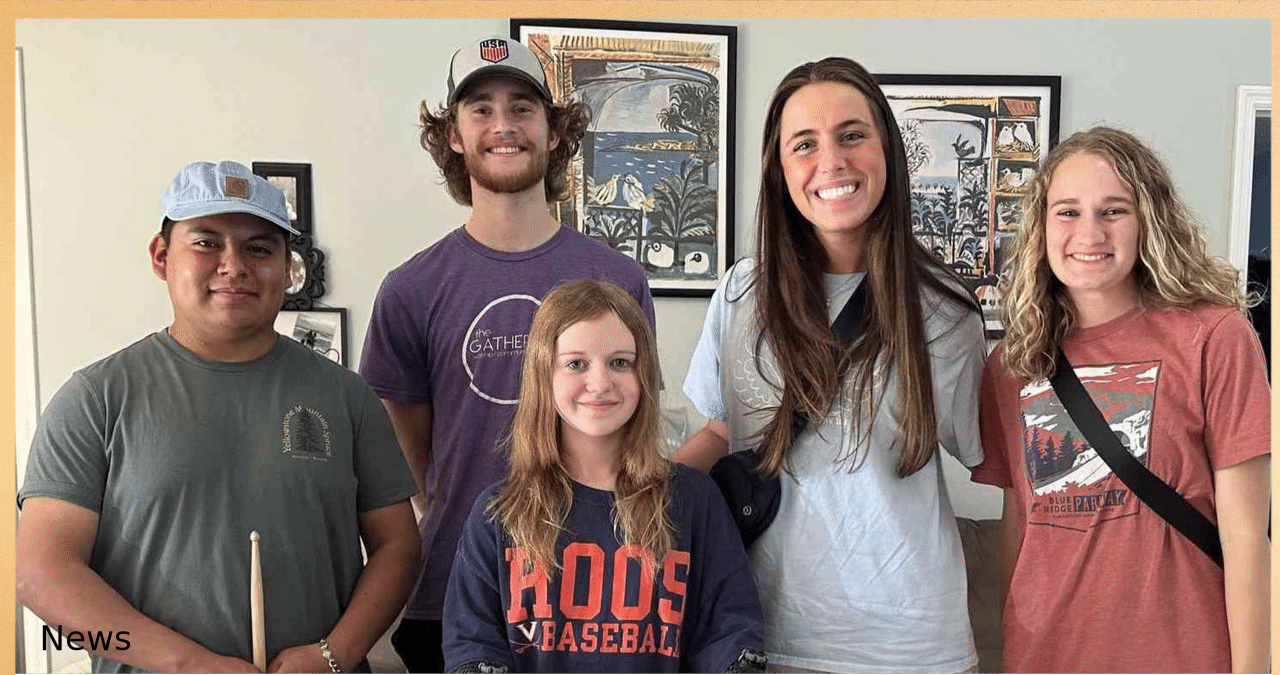

The engineering students at Tennessee Tech were contacted by the band director with a unique challenge. They were tasked with designing a prosthetic arm that could hold a drumstick comfortably and be durable enough for regular use. The entire process of the class was documented on the Technical Engineering for Kids webpage.

Zakary Henson, a mechanical engineering student, shared that the team’s initial step was to inquire about Sauvie’s requirements and preferences. They asked numerous questions to ensure that they had a clear understanding of her needs.

During an interview with WKRN, Henson shared that they are considering various aspects of the design for the mallets. Apart from playing the drums, they are also exploring if the player can use the mallets to play a xylophone or other similar instruments. Additionally, they are working on securing the mallets to the hand and figuring out if different handles will be required. All in all, there are many questions to be answered, and Henson and the team are putting thought into all of them.

The Tennessee Tech for Kids organization deserves our appreciation for their courteous efforts.

After discussing the project with the client, Sauvie, the students proceeded to create concept designs and take measurements. They collaborated closely with Sauvie to ensure that the chosen design met all of their requirements.

The process involved a lot of trial and error, with numerous iterations made on a 3D printer.

Branson Blaylock, an engineering student, told WKRN that they conducted a series of tests where they repeatedly printed a set of designs for 24 hours each time. Their goal was to see if they could achieve this feat.

Sauvie’s prosthetics are now a perfect fit after a semester, providing her with breathability and flexibility. These prosthetics have given Sauvie the ability to create the sound she has been striving for.

According to Sauvie, she feels thankful that they showed such eagerness and perseverance to make it work.

The engineering students express their gratitude as well.

Henson expressed her desire to use her mechanical engineering knowledge to assist others. Witnessing the product fit seamlessly on the recipient’s arm was a particularly gratifying experience for her. “To get to see it actually fitting on her arm and everything, that was something that was so cool to see,” she said.